Hengde Company is a leader in the field of industrial temperature control and has long focused on the research and development and manufacturing of mold temperature controllers. With advanced technology and rich experience, Hengde mold temperature controllers have excellent performance, stability and accuracy, providing reliable solutions for the temperature control of reactors, and are widely used in reactor systems in many industries such as chemical, pharmaceutical, and food.

1. The working principle of oil mold temperature controller in reactor

As a temperature control device for reactors, oil mold temperature controllers are widely used in chemical, pharmaceutical, and food industries, mainly for precise control of the temperature in reactors. Its working principle is to use heat transfer oil as a heat transfer medium, use an electric heater to heat the heat transfer oil, and then use a circulating pump to transport the heated heat transfer oil to the jacket or coil of the reactor to exchange heat with the material in the reactor, thereby achieving control of the temperature of the material in the reactor.

2. The following are the application scenarios of reactor oil mold temperature controller in different industries

(1) Chemical industry

(2) Pharmaceutical industry

(3) Food industry

3. Application advantages

(1) Accurate temperature control

The oil mold temperature controller can achieve high-precision temperature control, usually reaching a temperature difference of ±1°C, which is particularly important for chemical and pharmaceutical processes that require strict control of reaction temperature. At the same time, the oil mold temperature controller can be customized according to different process requirements to meet various complex temperature control requirements and is suitable for different types of reactors and production processes. Whether it is chemical products, medicines or foods, they can all benefit from a stable temperature environment.

(2) Improve product quality

Accurate temperature control can make the chemical reaction in the reactor more stable and controllable, reduce the occurrence of side reactions, and thus improve the purity, quality and consistency of the product.

(3) Improve production efficiency

The heat transfer oil has a high thermal conductivity and specific heat capacity. The oil mold temperature controller can quickly heat and cool the reactor and shorten the reaction cycle. At the same time, stable temperature control can reduce equipment downtime and product defective rate caused by temperature fluctuations, and improve production efficiency and equipment utilization.

(4) Reduce energy consumption

Hengde oil mold temperature controller adopts advanced energy-saving technology and intelligent control system, which can automatically adjust heating and cooling power according to the actual temperature demand of the reactor, avoid energy waste, and reduce energy consumption costs in the production process.

(5) Extend equipment life

A stable temperature environment can reduce the thermal stress caused by temperature changes in the reactor, reduce the risk of equipment wear and damage, extend the service life of the reactor, and reduce equipment maintenance and replacement costs.

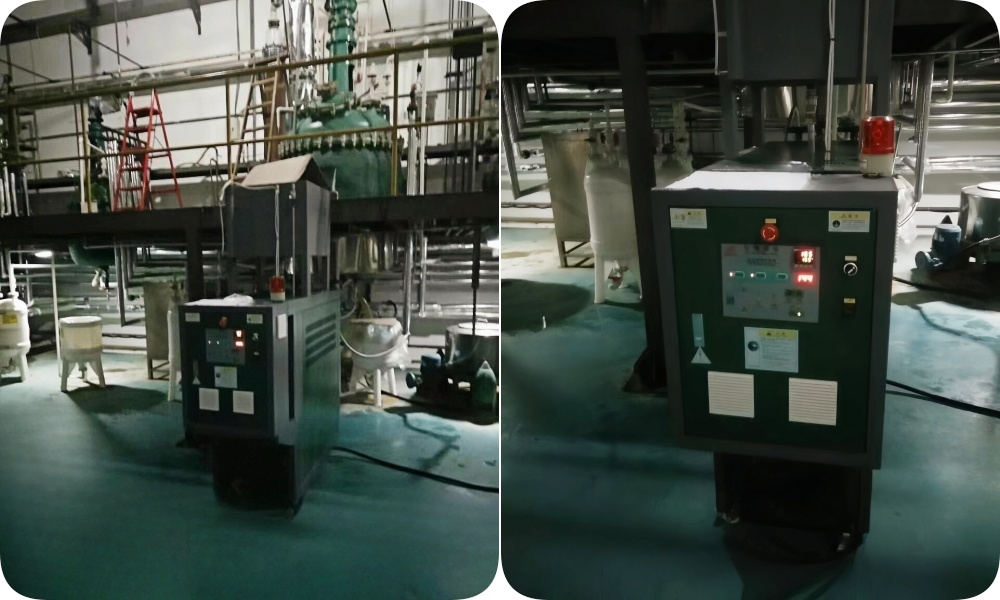

4. Application Case

When a chemical company was producing a new type of plastic additive, the original temperature control equipment could not meet the temperature accuracy requirements of the reactor, resulting in unstable product quality and a high defective rate. After the company introduced Hengde oil mold temperature controller, the oil mold temperature controller was able to accurately control the temperature in the reactor within the range of ±1℃. The quality of the product has been significantly improved, and the defective rate has been reduced from the original 15% to less than 3%. At the same time, the production cycle has been shortened by 20% and energy consumption has been reduced by 15%, bringing significant economic benefits to the company.

5. Selection and maintenance recommendations for oil mold temperature controllers

Choose Hengde, Choose Perfect Mold Temperature Controller!