In recent years, with the improvement of shipbuilding technology and the development of offshore fishing, marine chillers have attracted more and more attention. Marine chillers are high-end models designed for marine environments. The use of environmentally friendly refrigerants, improved energy-saving effects, optimized structures, reduced consumables, reduced volume, reduced weight, reduced noise, and improved comfort are all important features that reflect the development of marine chillers to meet the needs of ship modernization.

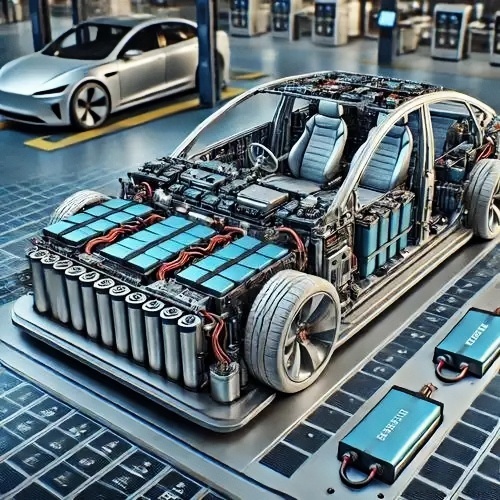

Marine chillers usually use a vapor compression refrigeration cycle, and their working principle is similar to that of land-based chillers. It compresses the low-temperature and low-pressure refrigerant gas into a high-temperature and high-pressure gas through a compressor, and then sends it to the condenser, dissipates heat through the cooling medium (usually seawater), and condenses the refrigerant gas into liquid. The liquid refrigerant enters the evaporator after being reduced in pressure by the throttling device, and absorbs the heat of the cooled medium (such as air, water, etc.) in the evaporator, thereby achieving the purpose of refrigeration. The cooled medium is then transported to the equipment or system that needs to be cooled through a pipeline to complete the entire cooling cycle.

The main components of marine chillers are compressors, condensers, evaporators, throttling devices and control systems. The compressor is the core component of marine chillers. Common types include piston, reciprocating compressors, screw compressors (semi-closed or open) or scroll compressors. The condenser usually adopts a shell and tube structure, the interior is generally nickel-copper, and the cooling medium is seawater. In order to prevent seawater from corroding the condenser, the condenser is usually made of corrosion-resistant materials, such as titanium alloy, stainless steel, etc. The evaporator usually adopts a shell and tube or plate structure, which can be replaced with stainless steel according to customer needs. The design of the evaporator needs to take into account the space limitations and cooling requirements of the ship, and usually needs to have the characteristics of efficient heat exchange, small size and light weight. The function of the throttling device is to reduce the pressure of the liquid refrigerant discharged from the condenser, making it a low-temperature and low-pressure refrigerant liquid, and enter the evaporator for evaporative cooling. Common throttling devices include capillary tubes, thermal expansion valves and electronic expansion valves. The control system monitors and controls the operating status of the chiller to ensure the safe and stable operation of the chiller. The control system usually includes temperature sensors, pressure sensors, controllers, displays and other components. Marine control systems usually need to have high reliability and strong anti-interference capabilities to adapt to the complex electromagnetic environment of ships.

Hengde Marine Chiller:

When customers purchase marine chillers, the cooling capacity is basically 12HP+;

The main engine uses compressors such as Bitzer, Copeland, and Hanbell, which are of stable quality and reliable operation;

The shell and tube heat exchanger designed for seawater is adopted, and corrosion-resistant materials such as nickel white copper, aluminum brass, titanium alloy, and stainless steel are used, with high heat exchange efficiency and long service life.

Control system: Industrial-grade centralized control system, Chinese and English operation interface, you can check the unit operation status at any time, adjust the working mode, accurately control the matching of the unit's cooling capacity and cold load, ensure the unit operates at normal efficiency, and reduce operating costs. It integrates multiple protection functions such as water flow, low temperature, high and low pressure, antifreeze, reverse phase loss, delayed start, overload, overtemperature, and oil pressure difference. Accurate control can control the temperature within the range of ±1℃, easy to operate, stable and reliable, etc.

Solution:

Five years ago, a marine shipyard in Maldives found us. According to the feedback from its customers, the current ships have no refrigeration equipment. Many fish died after being caught on board due to the large temperature difference. Therefore, they wanted to equip all ships with chillers. Since equipped with our chillers, the water temperature has been maintained to keep the fish fresh. The customer was impressed by the performance and function of our chillers. Now they are building a new factory to build ships and prepare to equip all subsequent ships with Hengde's marine chillers.